Indian Start Up Ecosystem for Hardware Start Ups

About Us

Atomberg Technologies was founded in 2012 by IIT Bombay alumni. We are the manufacturer of India’s most energy efficient ceiling fan named Gorilla. It uses BLDC technology and consumes just 28W thus reducing power consumption by more than 65%. Till date, more than 50,000 fans have been manufactured and sold to clients across the country

The Start Up Ecosystem

With the government’s focus on start ups, the eco-system has definitely improved. Today, there are good quality incubation centres in all premier institutions in the country to foster the spirit of entrepreneurship. Our company was incubated at the incubation centre at IIT Bombay. The support and nurturing in the initial days were very important for us. We were also part of another accelerator program which was a joint venture of UNIDO and MSME( Global Cleantech Innovation Program) where we were the global winners in the category of energy efficiency. This program also helped us a lot in networking with the clean tech community at a global level.

Challenges Faced and the Solution

But not everything is hunky dory. If you are a hardware start up, and that too in the cleantech space, there are hundreds of challenges. Some of them have been listed below:

a) Prototyping and Manufacturing

If you are developing an innovative hardware product, prototyping is a huge challenge. It is a time consuming and costly process. If prototyping was tough, manufacturing for us was 100 times tougher. The lack of professional vendors in our space(ceiling fans) put us through a lot of difficulties. Material would usually be delayed by days and sometime even months. And with this being a completely new product, there weren’t many alternatives for us, and we had to rely on the same set of unprofessional vendors. So, all our planning had to done keeping in mind a 30 day delay. This adversely affected our working capital management, but this was the only way out.

Fig 1: Stator Used in our Fans

But once we had some scale and were giving continuous and repeat business to the vendors, we started having more bargaining power. We could become stricter with the timelines. We could also demand credit to manage our working capital.

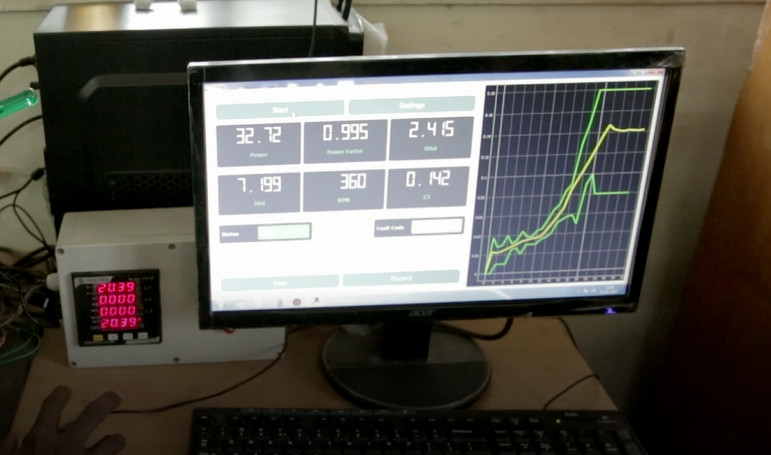

Fig 2: Computerized testing at Atomberg

b) Recruitment

The next challenge is team building. Unless you are able to pay significantly high salaries, it is almost impossible to attract top talent. And the most important success factor for a start up is a strong core team. Although it was difficult for us, but we spent a significant time on recruitment. We were looking for guys who shared our vision of being a disruptive force in the world of consumer appliances, and people who were looking to be with us for a long time. And we were lucky to find a core team who were in it for the long term, and not looking at immediate monetary gains.

c) Funding

Another challenge for start ups in the hardware space is the ability to raise funds at an early stage. There is a significant investment needed to set up the assembly plant and build the early team before generating any revenue. And since there are so many factors involved( success of manufacturing when done at scale, adhering to timelines etc) where we do not have control, investors are generally wary. Luckily for us, with our IIT-IIM background, we were able to convince a couple of investors to back us at an early stage. Having a solid business plan along with initial traction in some markets went a long way in enabling us to convince the investors.

d) Sales

The biggest challenge for any start up is sales. Since you are an unknown entity, nobody is ready to believe your innovation. And if they believe, they will just laud you for being innovative, while not purchasing your product. Since we were manufacturing energy efficient ceiling fans, we were not sure who our earliest market should be. Then we set to find out the segment which had the biggest pain due to high electricity bills caused by ceiling fans. With a bit of market survey, we found that ceramic industries were using huge numbers of fans in their industries. And most of these fans were running 24*7. And bingo, we had a market which was ready to accept the product. So, instead of chasing clients in every sector, we decided to focus on quality and service for the ceramic industry. And once the initial clients were satisfied, we got huge business from the industry as word of mouth spread about our fans. So, the biggest lesson here is to service and satisfy your existing customers rather than just chasing new clients.

Fig 3: Atomberg’s Gorilla Fan

Atomberg’s way ahead

Every year, 4 crore ceiling fans are sold in India. The number of BLDC fans sold is not even 0.5% of the market. Our dream and vision is to make sure that one day all ceiling fans in India are replaced with energy efficient BLDC ceiling fans. This will give electricity access to more than 5 crore Indians who do not have access to electricity today.

Author’s Name- Arindam Paul

Designation- Head, Marketing and Strategy

Start Up Name- Atomberg Technologies Private Limited